Trenchless replacement and new installation of mains pipelines

For the renewal of distribution pipelines in urban areas, our hydros® technology offers distinct advantages. It is very economical, especially in confined spaces or with a high density of installed pipelines. A drastic reduction of earthworks, removal of old piping, and vibration-free works in the same channel are further 'green' features.

Customized, proven and efficient technical equipment is ready for use in the following applications:

hydros®PLUS: pipe replacement

The original is known as a press-pull process for exchanging pressurized pipes made of brittle materials.

hydros®STEEL: pipe renovation

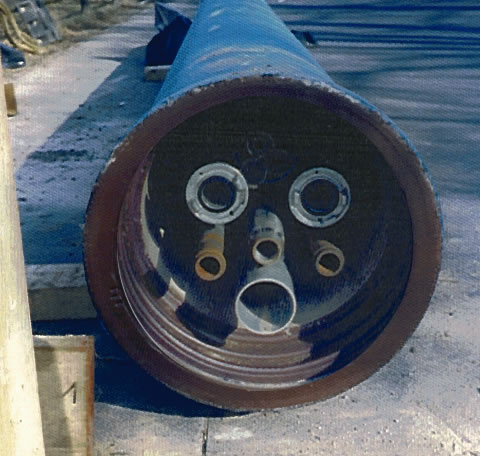

Especially for the renewal of pipelines made of ductile materials. A special cutting expansion head is used with the hydros®PLUS extraction device.

hydros®STAR: installation of new pipes

An additional pilot drilling machine and if necessary a flush head can be used in this process for installing new pipes or replacing them with with larger dimensions.

Of course our trenchless technologies comply with all of the DVGW regulations for mains supply pipelines.